In general, cooling systems are used for internal climate control of living and workspaces, temperature control of products, computers, or machines. Stable cooling cycles are important to create comfortable indoor climates but also to ensure efficient production processes and consistent product quality.

However, in our experience problems arise when the characteristics of cooling systems are overlooked or when they are treated merely as heating systems. This starts with the design or installation: for example, condensation must be considered in the choice of materials or the insulation. Higher flow rates of the system water or in the case of glycol also higher fluid viscosities have an impact on the selection of the right components.

But there are also additional requirements on operation or maintenance: the lower water temperature leads to increased hydraulic problems due to air, but even more attention needs to be paid to, for example, corrosion or microbiological growth and the resulting consequences in a cooling system.

If these points are not taken into account, this usually has a direct impact on the system performance, and the risk of system failures, malfunctions, and downtimes is increased. Often it ends up in high operating costs or replacement of parts. But far worse, and often difficult to quantify, are the costs of lost production or annoying inconveniences for the end-user.

Combined systems that need to provide both efficient and reliable heating and cooling add to the complexity of their engineering: especially pressurization is a challenge. Furthermore, HVAC installations today are expected to be energy efficient. Governments worldwide, through regulations and subsidies, encourage compliance with industry standards and energy-efficient performance.

So, you want to secure your investment with a system that is both designed and operates as it is supposed to during its functional life. This is definitely possible!

Balancing and optimising the quality of system water in closed cooling systems

We, at Spirotech, have been working with our customers for decades to optimize the design or performance of their cooling systems with solutions that have proven their (cost) efficiency over time.

We provide a service to quickly identify the water quality problems in your system, consisting of water testing kits that can be used onsite, or extensive analysis in our laboratory.

Based on test results we discuss the cause(s) of the problems and provide you with advice on how to condition and maintain the water quality. Our local colleagues can also support you with the implementation of the required improvements that will quickly boost the performance of your cooling system.

Of course, we help to fight the symptoms, but we also want to prevent problems

It makes perfect sense… covering every eventuality

Over time, pressure loss, corrosion, air, and dirt will reduce the system water quality in your cooling system. The following symptoms may then present themselves:

- Hydraulic issues

- System failure or downtime

- Increased energy consumption

- Reduction of system life

- Increased service costs

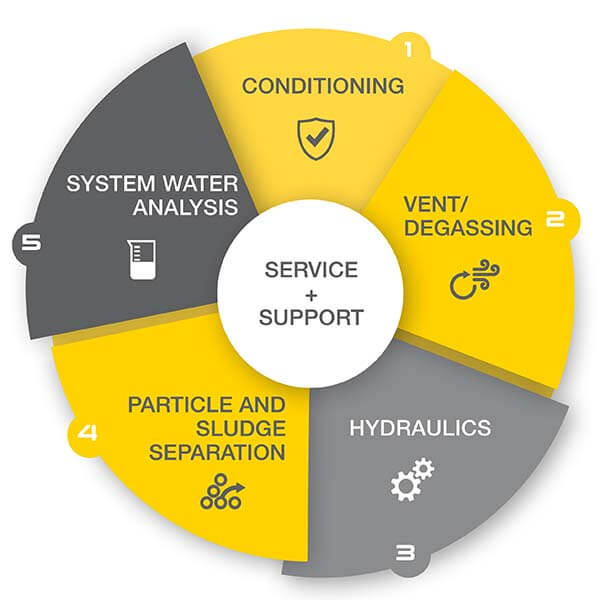

Our solutions for your cooling system

Conditioning

SpiroPlus - flushing agents and water additives

SpiroPure - fill and refill systems

Air removal / deaeration

SpiroTop - automatic air vents

SpiroVent - microbubble deaerators

SpiroVent Superior - vacuum degasser

Hydraulic balancing

SpiroCross - Hydraulic balancing with air and dirt separation

Particle & dirt separation

SpiroTrap - dirt separators (available with magnet)

Air deaerators & dirt separators

SpiroCombi - removal of air and dirt (available with magnet)

Pressurisation

SpiroExpand MultiControl Cool - Automatic pressure monitoring and control

System water analysis

SpiroCare - water sampling and analysis service

Service & support

Advice and support in the implementation of individual solutions with an exceptionally long guarantee of up to 20 years.

More information on Cooling and our solutions

Get in touch with one of our experts